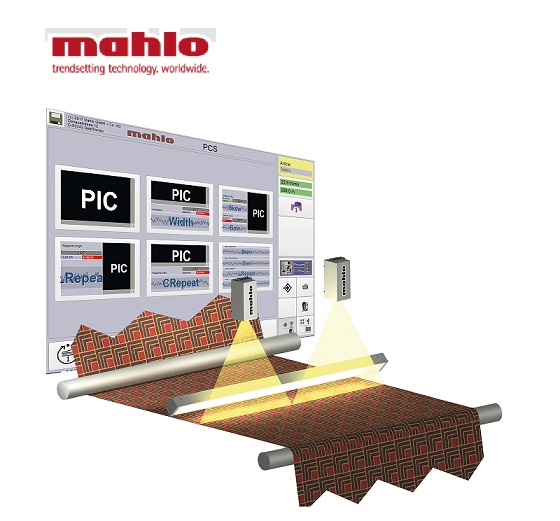

Pattern and distortion control

The leading pattern detection system using camera technology. The repetitions of printed, woven or tufted patterns are evaluated according to certain algorithms and are used for measuring, correcting and evaluating distortions and patterns.

The system uses one or two cameras, depending on the width of the product, to detect the position of the pattern and automatically and continuously determine the pattern repeat, as well as the product width, and together with a straightening machine align the product distortion based on the recognized pattern.

- Patcontrol PCS/PDS: (Pattern Distortion System) detects and controls bowed and skewed designs

- Patcontrol PCS/PRS: (Pattern Repeat System) monitors and controls design repeat using various standardized patterns.

Product highlights

- Modular assembly

- Measures repeat and straightens patterns simultaneously

- The very latest high-tech line cameras

Customer benefits

- Uninterrupted monitoring and logging of actual product quality

- Savings in raw materials and energy at the manufacturing stage

- Increased productivity

Hotline

Hotline anhnghisonhcm

anhnghisonhcm